Solving Hard Problems

Starts Here.

Most AI platforms break at multiscale complexity.

Ours was built for it – accelerating development of complex physical systems, shrinking iteration cycles, optimizing manufacturing processes, and getting engineering breakthroughs to production – fast.

Book Demo

The Hard Problems We’re Built to Solve — Fast.

Manufacturing Process Optimization

Scale R&D to production faster by rapidly identifying optimal process recipes and optimizing high-dimensional process inputs in real time using available data.

Materials Discovery and Property Optimization

Accelerate materials development optimizing for target performance with the fewest experimental and simulation cycles.

Simulation Acceleration and Optimization

Speed up high-cost simulations, reduce design iterations, and explore more of the solution space with fewer trials.

The MIND Platform: Built for Engineering Complexity

An integrated platform that combines domain knowledge, simulation, ML, and GenAI

to solve your toughest problems at scale.

Data Catalog

Locate, filter, and structure domain-specific data from fragmented sources—ready for simulation, modeling, or training.

Machine Learning

Build interpretable models that reflect real-world physics and variability—using domain-aware ML, not just curve fitting.

Optimization

Navigate tradeoffs across 1,000s of variables with multi-objective optimization tailored to engineering constraints - from R&D to manufacturing yield.

Active Learning

Continuously improve models by targeting the most informative data—especially in sparse or evolving environments.

Inverse Solver

Work backward from performance goals to derive input combinations—built for inverse design in complex physical systems.

App Hub

Rapidly build and deploy custom engineering apps—modular, scalable, and integrated into real workflows from day one.

Why Multiscale Works When Others Don’t

We don’t just model forward—we start with the outcome you want and work backwards to get there. Our approach blends physics, data, and decision logic to solve engineering problems others can’t touch.

We start with your target outcome and solve backwards—using a class of generative AI models to identify the inputs that get you there.

We handle sparse, noisy, and high-dimensional data—and use Bayesian optimization to systematically guide learning towards the most informative data.

Traditional optimization methods get stuck on local peaks. Our generative models explore complex, high-dimensional spaces to find the global optima—fast, reliably, and at scale.

We integrate data from your physical systems and simulation models into one continuously learning workflow to build dynamic digital twins for high accuracy decision support back to the physical system.

Bayesian probabilistic modeling help teams quickly find the best solutions—especially when data is limited, noisy, or evolving.

MIND recommends next-best actions, with guidance grounded in interpretable, physics-informed models.

We make model behavior transparent—improving trust and accuracy by combining physics-based logic with explainable ML.

Proof, Not Promises

Hard numbers. Real savings. From real customers slashing test cycles, cutting simulations, and improving yield.

From 10X reduction in testing stages

With <10% loss in accuracy

50% in physical trials

Solving Multiscale Challenges

Across Every Engineering Vertical

Semiconductors

Analyze die-level test data, predict overlay drift, and optimize yield with physics-informed AI – from early design to fab-scale production.

Automotive & EV

Optimize high-dimensional designs under performance constraints using AI-driven topology modeling. Qualify new materials faster with high-throughput screening for new product development.

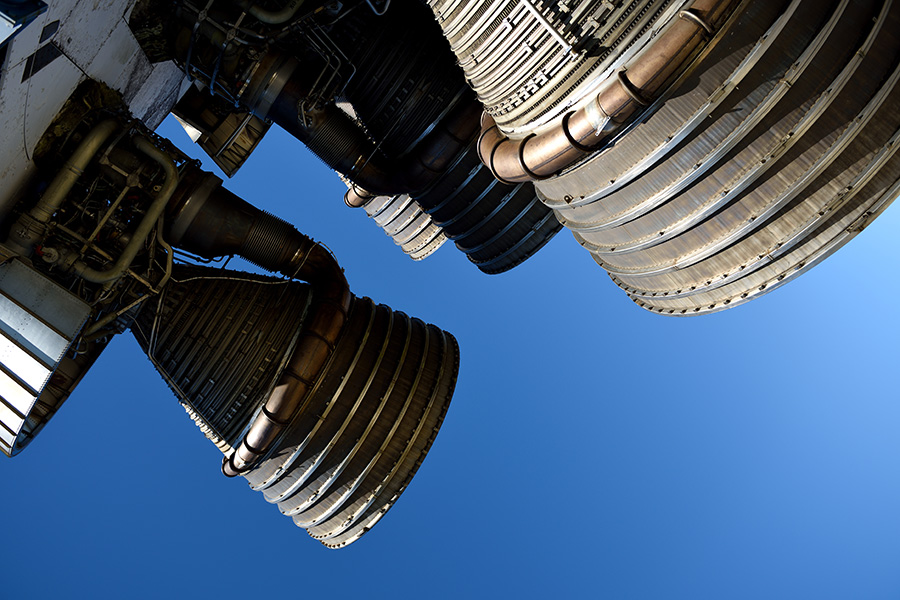

Aerospace

Design lighter structural components and improve production yield by reducing physical testing and part variability.

Metals & Materials

Correlate process inputs with material properties, optimize yield, and accelerate alloy development with fewer experimental cycles.

Chemicals & Polymers

Combine AI with molecular simulations to explore formulations, reduce validation cycles, and optimize processing conditions.

Energy & Utilities

Model complex energy systems, optimize control strategies, and validate digital twins with AI-augmented simulation.Solving Hard Problems Starts Here.

Let’s solve your’s next. From simulation bottlenecks to process variability and yield loss — tell us what you’re up against. We’ll dig in together.